|

Naturally in the beginning is the harvest, which is unfortunately

caused by a bare blow, because reforesting just happens occasionally. As experience

shows the central third of a bamboo pipe has the greatest firmness. First of

all the pipes were cut bit by bit to dry them 6 - 12 weeks on a wooden

storage place. If you take into consideration, that every bamboo was exposed to

individual conditions during growth, itīs only natural that every pipe has different

properties. So you arrange all bamboo pipes by length, straight, functional

abilities, etc. Additional you make a prechoice which pipes you could insert

into the suitable part of the bridge, because in some spots you even need curved

bamboos.

After the drying the braids and the moss were washed off, and the

little walls inside the pipe were stuck through. So it was possible to

waterproof the bamboo actually and completely, because just the smooth zones

inside are able to take up the salt solution. Normally in Columbia people use

benzine or pentachlorphenol for this process, but Jörg Stamm refused and decided on

a waterproof solution of bor.

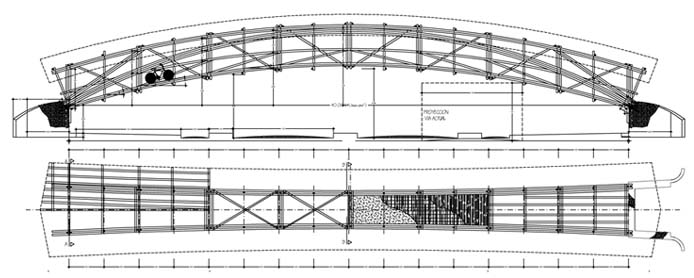

In the next stage the first curve construction will be made of one

piece on the ground. To put the geometry of this bridge with very simple measures at

the face into action, people served some tricks. At first they put up with the help

of a tightened rope the zero line, which will correspond in the end to a

horizontal line (here the lower side) of the bridge. For this step you choose the

greatest possible area in the surrounding, where you can measure and mark the

distances of the carrier elements. To put on exactly rectangular the correct

height of every vertical bar, you span a triangle with the help of a second rope and

fix the bamboo bar by means of the Pythagoras sentence. First of all you mark

this spot.

At this mark the bamboo bar will be drilled through and a metal bar

will be hit through the hole about 30 cm into the ground.

12 cm of the metal bar should be visible, so you can fix the curved

bamboo pipe in this centre.

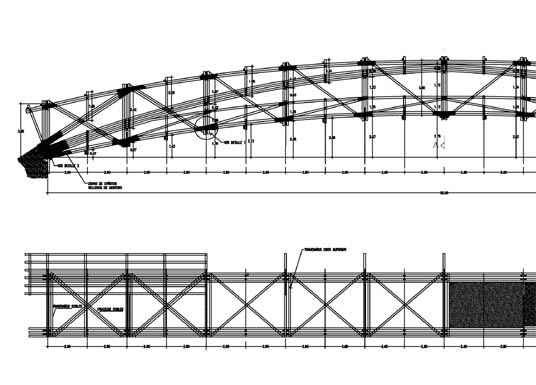

Connections

To produce a very long and loadable pipe out of several little

bamboos, the intersection should be close to the second or third knot. Then

you process the inside of the pipe and break through the little walls to lay in a

little metal rod. Now the mortar can be filled in. The distance of the cuts of these

combined carrier elements should amount at least 1.5 m.

By curves of static effective pipes, which lay on top of each

other, the knot should better be moved. this principle is known from the

brickwork building, too.

During time of construction it is necessary to connect the pipes

temporary, for this a strap will be put on which keep the bamboos in the

corrct position. Later on the holes for the screws will be drilled and the

connection gets durable. This screw connection should be close to the knot, though

you have to pay attention not to tighten the screws too much, because there is the

danger of crushing the pipes.

To resist the arising thrusts during compression, thin metal

rods will be laid in the appropriate spots in the "beam".

To prevent the rods from crushing the pipes under compression, the

knot will be filled with mortar, too. For this it is necessary to drill a hole with

a minimum diameter of 1 cm to fill in the mortar as good as possible.

|