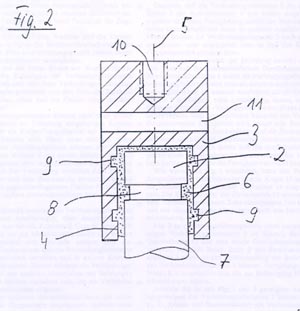

possible inner parts

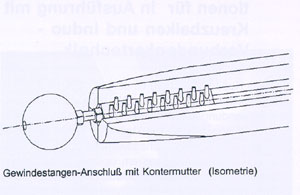

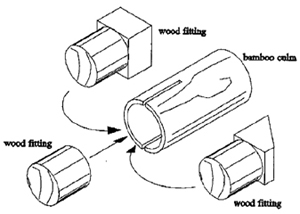

Woodcore connection. A piece of wood can be used and glue can be employed to stick it to the inner surface of the bamboo. Any normal glue provides a capaity far larger than that of bamboo in the tangential direction.

Two slots are needed in the bamboo cane to control cracking during the insertion of the wood cylinder.

The wood fitting can be extended outside the culm to meet the outcoming piece of wood from other elements, then normal wood construction methods can be used for connection.

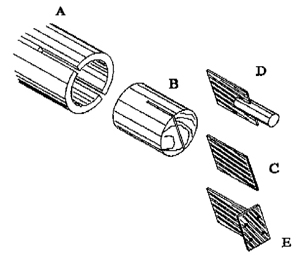

connecting system

Woodcore connection. The steel plate C is introduced in the slot of the wood cylinder and glued to it with a mixture of epoxy resin and portland cement. The plate is projected, so that its outer extreme can be adapted for different applications, as indicated in the details D and E.

Systemadvantages are its low price and the availibilty of the parts.

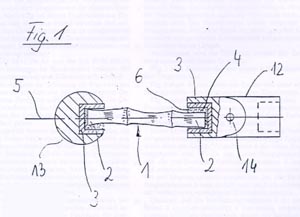

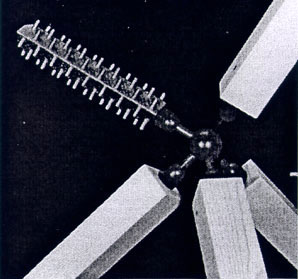

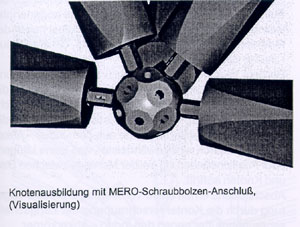

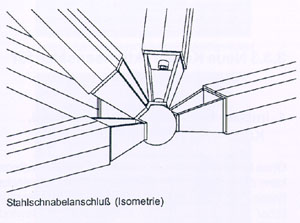

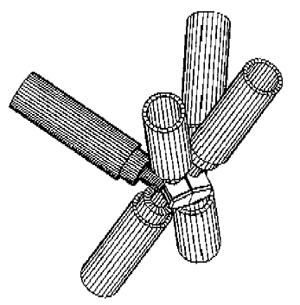

space truss, with centre steelbox element

In plane or space trusses, the plates from two or more incoming elemets can be pre-welded to eachother and then the rest of the connection can be assembled.

The figure shows a connection in which a small box is made of steel plates, so that the faces are prependicular to the axis of the incoming elements. The steel tips are then welded directly to those surfaces. Welding is thought of here because it is cheaper than machining of the tips, but in some cases tis can be achieved as well.

Information: Fundamentals of the Design of Bamboo Structures [pdf]

by Oscar Antonio Arce-Villalonos (Costa Rica/ at TUEindhoven)