Structural Systems |

|

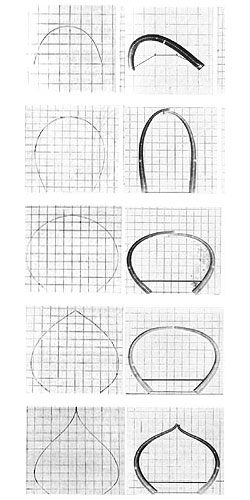

Form wird durch asymmetrische Biegelinie bestimmt

|

Arches

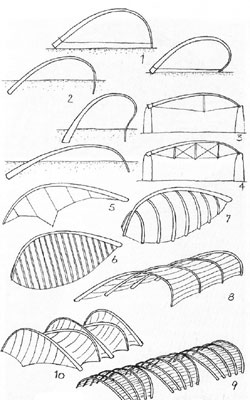

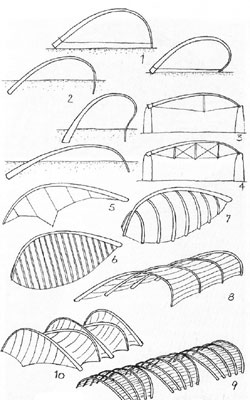

The form of a simple arch of conical vegetal rods is determined by the nature of the not symmetric deflection curve. As part of a structural system, the arch must be prevented from tilting. This can be achieved by anchoring it with tension-proof ropes or membranes, straight and even curved poles,or by restraining it. This type stabilisation requires an additional mass since the rod must be suitably rigid in the transverse direction.

Very different building forms can be produced by adding arches.

|

Symmetrie by addition of rods

|

Composed Curves

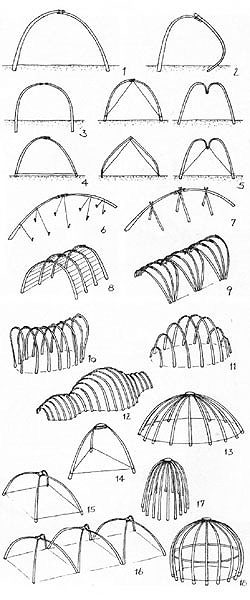

By adding several rods, you can achieve symmetric forms. The form depends depends on the way it's fixed to the ground.

Longer curves can be stabilised, which also reduces their structural length.

By adding several rods several room building constellations arise. By changing the length over elliptical floor plans, you can get domes.

Another possibility of shaping is the use of grid shells by croosing the rods.

|

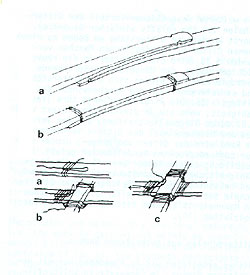

Grid shells / soft connections

Parallel, stiff connections

|

Different Connections

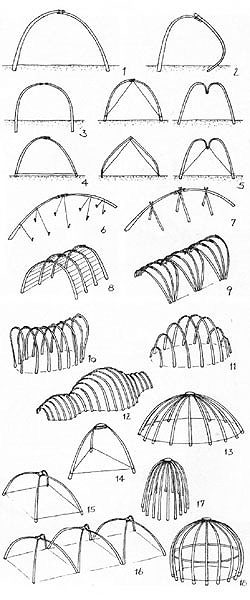

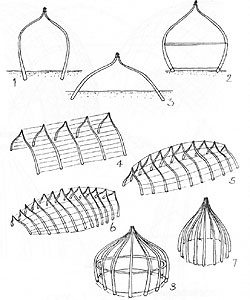

The way of connection of the singles rods builds up special kinds of shapes.

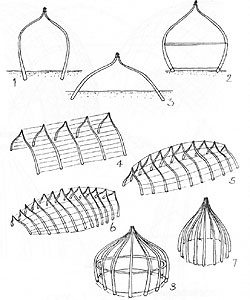

For example you can use soft connections, which causes pointed arches.

If you connect the rods parrallel, you get onion like geometries.

|

Constant / conical cross section

|

Survey

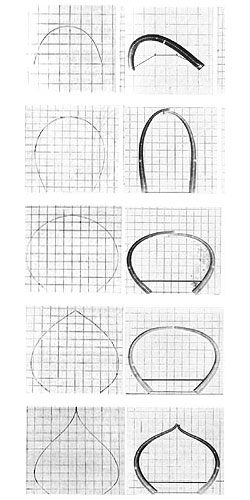

The image at the left shows an overall view of different curves in comparison to curved rods with a constant cross section. They were examined by trials with spring steel and conical foamed material.

|

Bamboo bridge in Japan

|

Building with curved bamboo

Normally only the lower half or lower third of the natural length of a bamboo cane is used to provide the load-bearing elements of a structure.With the majority of bamboo species,these canes are practically rigid and cannot be bent.When using bamboo cane in their full natural length,the bending of the upper sections of the canes with their relatively smalldiameter and wall thickness is possible and structurally sensible.

|

Grid Shells |

|

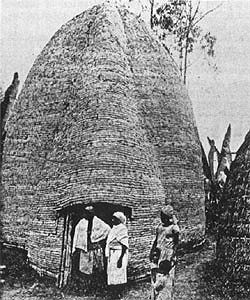

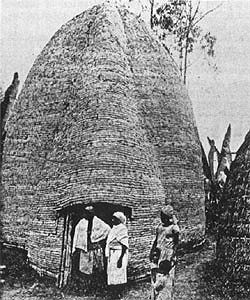

Bamboo Shed in South Ethiopia

|

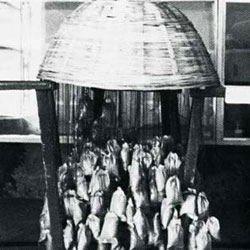

Modern structures made of split bamboo.If split canes are used in the load-bearing structure, the curved shape is unavoidable. In this manner relatively large buildings can be erected from split bamboo canes. A traditional example are the huts of the Dorse tribe which lives on the Gamu high plateau in southern Ethiopia, Africa. The huts of this tribe have a very charasteristic shape: a circular plan with a projecting entrance lobby

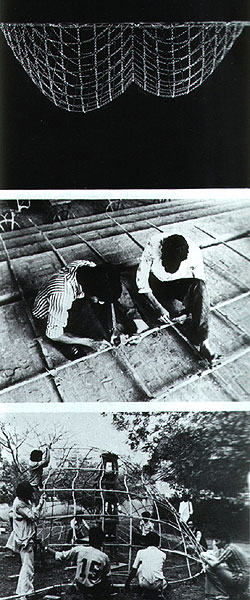

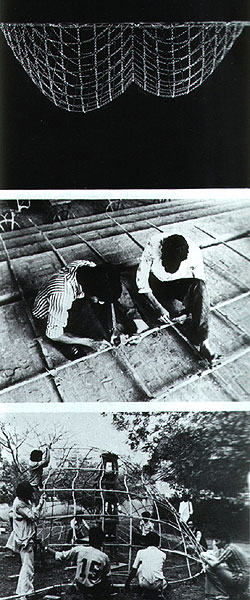

In collaboration with the School of Architecture (SA) of Ahmedabad, India, there has be the attempt to developnew contructional applications of bamboo by combining the great tradition of the bamboo craftsman with modern methods of lightweight construction.

|

Grid shell as transitions of the chain line

|

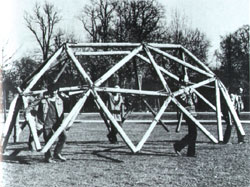

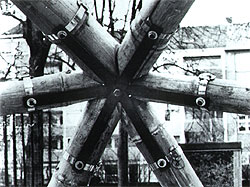

Grid shellsIn grid shells, which are a method of construction developed at the IL, relatively thin bars form a spatially curved load.bearing structure.The constructional principle is based on the idea of reserving the catenary line of a chain and making it into the thrust line of an arch.These are some important questions:

1. Determining the effect of irregularities in the bamboo grid bars on the shape and the load-bearing behaviour of the grid shells.

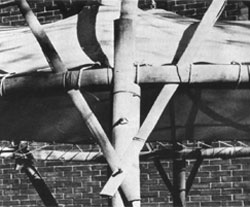

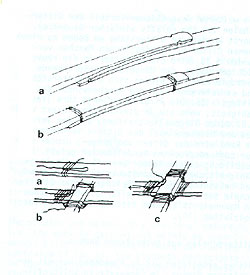

2. Development and testing of constructional details suited to the material such as the joining of the grid bars, the butt end joints of the grid bars, the design of the edge or boundary, the fixing of the grid to the boundary, options for fixing the form, etc.

3. Adapting the assembly and shaping methods to the requirements of the tied grid.

4. Detremining the load-bearing capacity of such structures and their feasible spans.

5. Developing and testing of possible roofing material and interior fitting equipement.

|

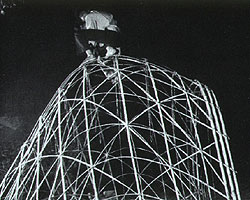

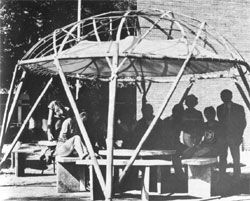

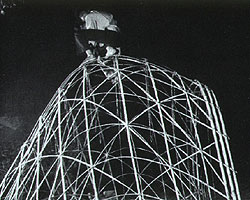

Finished grid shell

Details |

The studies have so far been carried out mainly on three experimental buildings:

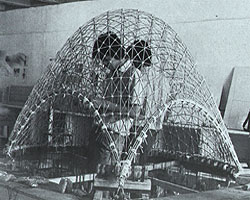

Experimental 1:

With the first experimental building( 1/8 full section, l=7,5m)the possibilities and possible problems of such structure were examined. The materal costed 80 DM.During this work the butt and tied joints of the grid bars were developed succesfully.The deformation was smallest at a surface of ca.122N/m2.

|

Stabilisation

|

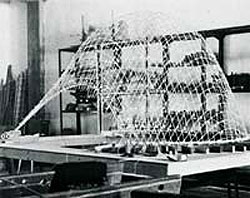

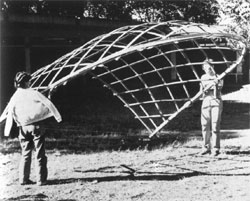

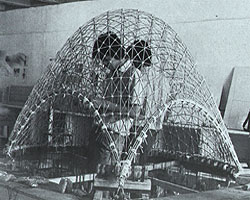

Experimental 2:

In November 1981 this experimental structure was altered. The smaller shel was overlaid by a diagonal secondary grid. The loading tests showed that the load-bearing capacity of this grid shell had trebled. The shell was also subjected to a concentrated load.

|

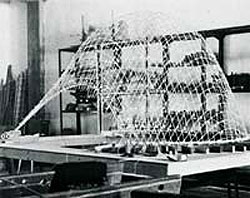

Modell in scale

|

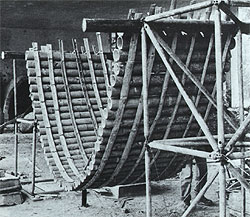

Experimental 3:

The third experimental building is a model of a grid shell with a span of 9 m and scaled 1:5. The results of the load tests showed that a corresponding grid shelwith secondary diagonal grid can support a load of 250-330 N/m² and a wind pressure of 500 N/m².

Conclusions

1. Split bamboo is a very suitablematerial for the grid shell construction technique.

2. The cross-sectional irregularities of the grid bars, which are inherent in the material,pose no serious problems.

3. The shape or dimensional tolerances caused by the irregularities could be reduced by an appropriate selection and arrangement of the grid bars within the grid.

4. The jointing of the structural elements developed from the traditional tying techniques have basically proven succesful.

5. The harmonius curvature of the grid bars is not distributed by the rope tie joints.

6. With large grid shells the grid has to be suitably prepared in order to facilitate its assembly and final forming.

7. The limit of the maximum spans of grid shells made from split bamboo is around 10m.This span limit is probably also dependent on the species of bamboo used.

|