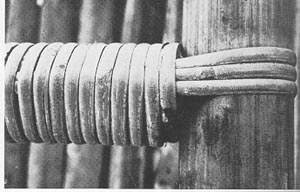

Connection with bamboo strips

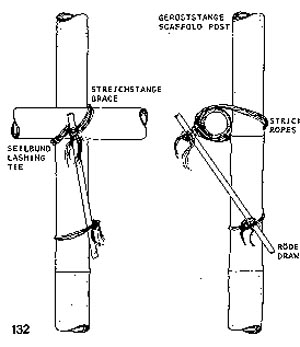

Lashing ties: The common type of connection at a joint is lashing. The ties are also of organic material and therefore provide optimal compatibility between the elements of the construction system.

Cords and ropes are made of bamboo

bark, bast, coconut- or sagopalmfibres. Nowadays also

plastic cords are used.

Bamboo ropes of twisted bamboo fibres are produced in

lengths up to 350m. They are more wear-resistant than

standard ropes. With a tensile strength of 720 kp/cm³ a

rope of an armīs thickness can bear up to 14 tons.

Binding wire is (as plastic cords

are) an industrial product.

Zinc coated wire has the same lifetime as bamboo.

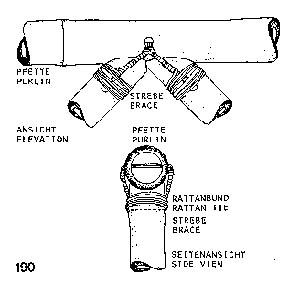

Fine handwork rattan connection

Plait strips: Usual plait materials are rind strips of bamboo, rattan or lianas. Soaked before use they are more pliable. When drying, the fibres shrink and the connection tightens.

Purlin and braces connection

Lashing ties - connection of a purlin and two braces with three drill-holes.

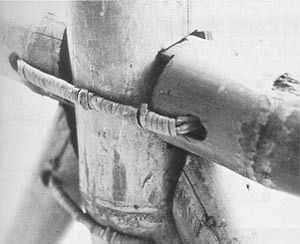

Rattan connection through drill-holes

Rattan tie to fix a plug connection

Another rattan connection

Friction-tied rattan connection. The end of the beam and the tie do the power transmission. If the connection is not tight enough, the beam may crack at the drill-hole. The additional bandage prevents the sling from slipping. If connected at a post nodium, the broader nodium in addition complicates slipping of the beam.

Variation of the connection above

Top of the post with drill-hole. If post and cross-beam are of the same diameter, the lashing tie replaces a stop at the side. A croossing bandage shortens the sling and prevents the post from sliding.